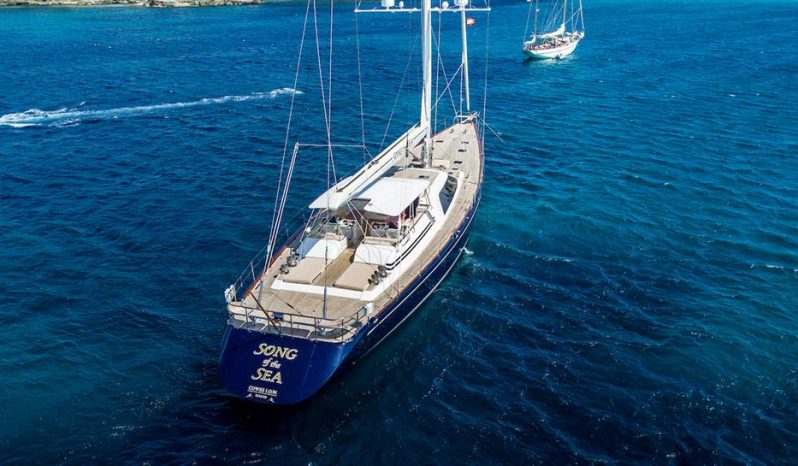

Often referred to as the most beautiful Swan, ‘Song of the Sea’ is undoubtedly one of the finest yachts afloat. As a sailing machine, she features a Southern Spars carbon mast and composite hull which enables easy, fast sailing with a global range. On deck, she offers exceptional comfort and volume with several areas where guests can sit and relax, including the large center cockpit which features twin dining tables and settees. The close proximity of the helms to the cockpit allow the helmsman to follow the conversation while keeping a hand on the sail trim via the fully automated push-button control system.

The interior is an exquisite blend of hardwoods, selected marble and custom fabrics that have been combined by expert Nautor craftsman under the watchful eye of interior designer Dick Young. The result is an incredible achievement of beauty and style that exudes a quality and pedigree that one would expect aboard the very finest superyacht. She has sleeping accommodations for up to ten guests consisting of a full-beam master cabin and three guest cabins, each with Ensuite head. There are separate crew accommodations for five with a crew dinette and entertainment center.

‘Song of the Sea’ has been exceptionally well cared for and in recent years, has undergone two substantial maintenance periods where absolutely no expense has been spared.

Recent Improvements

2015/2016

- Full exterior repainting of hull (Flag Blue) and superstructure (Oyster White)

- New antifouling

- Capping rail and companionway steps stripped and revarnished.

- Both rudder bearings replaced

- Keel bolts checked for correct torque

- Upgraded connections and buttons on boat helm station

- New Mastervolt 24/4000 inverter installed

- New AIS unit installed

- Both HVAC compressors replaced

- Watermaker low pressure pump motor replaced

- Routine preventative maintenance carried out on main engine and generator

2014/2015

- Mast and boom removed for five year service and new Oyster White painting

- Mekanord gearbox sent back to manufacturer for service and upgrades

- Marex gearbox/engine/propeller pitch control system also replaced with updated system

- New shaft seal and cutlass bearings installed

- PCs and interior PC monitors replaced

- Navigational chart plotting system replaced with new Simrad touch screen system including installation of new Simrad 4G broadband radar to compliment existing Nobeltec plotter and radar

- Watermaker high pressure pump given a service

- New Mastervolt 24/2500-230V inverter installed

- Bow thruster removed and given a new steel cylinder to replace old one

- DC service batteries given a full survey and discharge test with excellent results

- Routine preventative maintenance carried out on main engine and generators.

- New Castoldi jet 15 tender delivered in June 2015

2011/12

- Ultra sonic antifouling installed in engine room seawater chest

- Arid bilge, micro bilge water system installed in engine room and bilges

- Port and starboard generators top end rebuild, new valves and head gaskets, compression tests and fuel pump overhauls

- New headlining in engine room, new hoses and clamps and new piping

- Keel bolts tightened

- Atlas Shore Power system increased from 25KVA to 30KVA

- New 380V Air Compressor

- Watermaker Membranes replaced and salt water pump replaced

- Stern Thruster out sent back to Volvo and rebuilt

- New Doyle Dimension Main and Genoa

- Furling boom overhauled, hydraulic motor replaced and new locking mechanism installed

- Engine room overhaul, upgrading fuel system and lighting to LED

2010/11

- New hot water heater installed

- New pump and ancillary equipment on transmission

- New galley equipment and interior upgrade including

- Sound system

- Furnishings

- New bedding

- New air conditioning

2009/10

- Interior lighting changed to LED

- Mast out and reworked

- All New Memory Foam mattresses throughout

- Shaft pulled, new bearings

- Rudder out, new bearings and seals

- Hydraulic tank out and re worked

- New hull painting in Awlgrip Flag Blue

- All New Steering chain and cables

- Settee backs in Saloon cut out to make extra storage

- Second Set of Racor filters added for Day tank

- New Entertainment system throughout, Bang & Olufson Hard Drive with Plasma Screen TV’s

- New Leather in Saloon and Crew Mess

- New North Sails Gennaker

- New 125HP Yanmar in Tender

- New Magnatrons in Radars and New Screens in cockpit

- Dive Compressor overhauled

- Air dryer installed on pneumatic system

- Fuel tanks opened and cleaned, in line filters installed

2008/09

- New pneumatic system for doors and seals installed

- New batteries and inverters

- New tubes on tender and overhaul

- Decks sanded and recaulked

- New hatch surrounds and teak work done where needed

- New All Wood Cockpit Tables

- New cushions and fabrics in cockpit

- Steam shower installed in master head

- Shore Power Atlas bypass installed for use with correct shore power

HULL & APPENDAGES

Construction

The hull is of single skin construction using glass/aramid hybrid fiber reinforced vinyl ester laminate with carbon fiber reinforcements. A high proportion of the fibers are unidirectional, giving a stiff laminate with excellent strength and fatigue properties. Structural bulkheads are foam cored plywood laminated to hull and deck. Stiffener flanges are unidirectional lay- ups over foam cores. Engine beds are of GRP with steel inserts.

Hull Finish

Topsides are finished in flag blue Awlgrip paint– new 2016

Boot and cove stripes finished in oyster white Awlgrip paint – new 2016

Bottom is treated with three layers of epoxy primer and coated with two layers of black antifouling

Keel

The ballast bulb is a lead casting with antimony attached to a steel fin. Keel bolts are of high- tensile stainless steel.

Rudder and Steering System

Rudder is foam filled GRP with a tapered, lightweight, composite stock supported by two self-aligning roller bearings. An aluminum steering quadrant is bolted to the rudder-stock.

Twin 55” destroyer type wheels have teak trim and have 4.7 turns H.O. to H.O. Steering sheaves are bronze with stainless steel needle bearings. Custom GRP steering pedestals have integrated instrument pods for all sailing and navigation systems.

Dinghy Garage

Custom hydraulically operated transom door / bathing platform opens allowing access to lazarette and dinghy stowage. Inside is a Castoldi Jet Tender 15 with a dedicated fuel filling station. Storage for dive bottles and a high-pressure air outlet for filling bottles is provided. To starboard of the dinghy garage is a hydraulically operated passarelle. A hinged lid is fitted flush with the transom and provides access for the shore power cables, city water connection, cable TV, and telephone connections.

Forepeak

The foc’s’le is accessed via a deck hatch and has a watertight bulkhead aft. The interior is painted white and has stainless rails that double as footsteps and hangers for mooring lines, sheets and halyards. Shelves and hanging bars are installed for stowage.

Passarelle

A 3.5 meter hydraulically operated folding passarelle is recessed on the starboard side of the dingy garage. It can be operated by remote control as well as control buttons on push pit

Side Boarding Ladder

A hydraulically operated side-boarding ladder is recessed amidships on the starboard side. Halogen lights are installed on the steps. The ladder can be controlled remotely on a wandering lead.

DECK

Construction

Main deck is of GRP sandwich construction with closed-cell foam core, and glued and through bolted to the hull. High-density core under deck fittings. Laid teak decking, 60 mm wide on deck and coach roof, cockpit coamings and soles, all glued and vacuum bagged without screws.

Finish

Composite surfaces and superstructure are finished in Awlgrip Oyster White (new 2016)

Bimini

Semi permanent bimini top over cockpit Side screens for bimini with custom stainless fittings

Cockpit

On the port and starboard sides are “L” shaped sofas with seating for 8 to 10 persons. There are twin coffee tables that can be electrically raised and expanded into a dining table. On the forward end of the cockpit is a towel locker and a top loading drink fridge. Drink holders are in the settee armrests.

Steering Pedestals

Two customs Nautor made GRP steering pedestal with integral instrument with control panels port and starboard. Full engine, navigation, sailing instruments, winch and thrusters controls are at both pedestals

Hatches

On the fore deck there are two hinged hatches to anchor stowage and anchor windlass, teak covered hatches for propane locker, hose locker, and sail locker

Deckhouse windows are of tinted glass with electrically operated shades.

Pneumatically powered main companionway lockable sliding hatch.

Pneumatically controlled cockpit coaming sliding doors port and starboard

(2) hinged hatches to winch lockers outboard of mast

(2) hinged hatches to winch lockers on side decks

Inspection hatch for side boarding ladder on port side deck.

Tinted custom Nautor made hatches openable with screens and black out curtains of composite construction with tempered glass for:

(2) In crew cabin heads

(2) In crew staterooms

(4) In galley (1) in day head

(1) in starboard forward guest head

(1) deck window in control room

Two in main salon

Windlass

(2) Lewmar 6000 hydraulic windlasses are in the fore deck and are equipped with gypsies and warping drums. Anchors are deployed on (2) hydraulic arms that stow, with anchors attached, in deck lockers. There are (2) stainless steel 106 kg CQR anchors

Winches

(2) Lewmar 111 ST hydraulic reaching sail winches on the coaming aft of cockpit

(2) Lewmar 88 ST hydraulic mooring winches on the coaming aft of cockpit

(2) Lewmar 88 ST halyard/topping lift/preventer winches near the mast

(1) Lewmar 88 ST working jib halyard in the bilge near the mast

(1) Rondal RW 4000 main halyard winch under the floorboards at the mast

(2) Rondal RW 4000 mainsheet winches in the helmsman’s seats

(2) Rondal RW 6000 jib sheet winches in deck lockers outboard deckhouse

(2) Rondal RW 4000 running backstay winches in the lazaretto

(2) Rondal runner control line winches in deck lockers near main shrouds

Anchoring and Mooring

Two CQR 120 kg anchor on hydraulic powered swinging arms that fold into deck locker

Fortress FX-125 stern anchor

(2) 120 m lengths of 16 mm stainless steel anchor chain for CQR anchors

Assorted mooring lines

Assorted fenders

General

Sleeps ten in one master and three guest cabins. Two crew cabins accommodating up to five crew

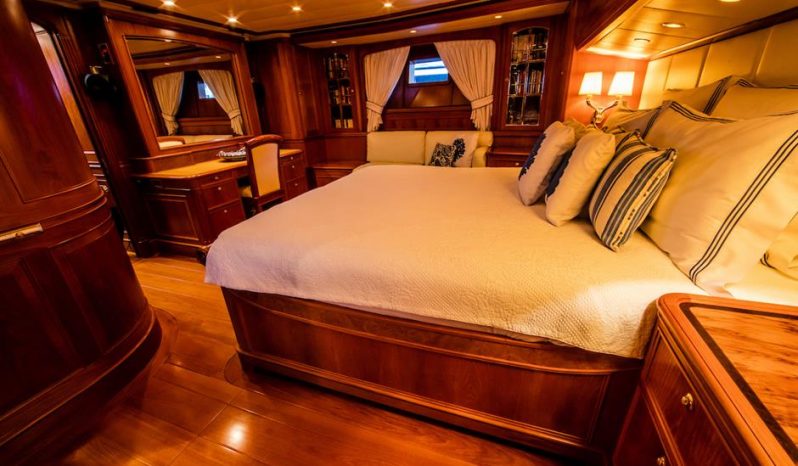

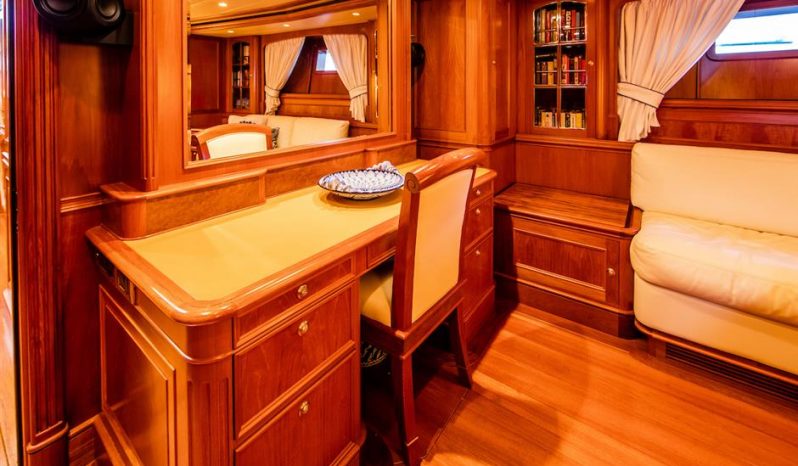

A great deal of effort was put into the interior design of this vessel, creating a yacht of timeless classic beauty and perfectly balanced proportions. Each room is a visual delight, an elegant blend of exotic hardwoods with the finest silks, leathers and stone available.

INTERIOR

Master Cabin (Aft)

Centerline queen sized berth, settees on port and starboard

Writing/vanity desk with mirror forward with chair. Mirror retracts electrically to reveal 42″ television

Drawers, bookcases and storage lockers either side outboard and aft

Ensuite head finished in Azul Macaubas marble and teak with gold plated taps and fittings

Separate shower stall, washbasin, mirrors, storage lockers and Tecma WC

Aft Port Guest Cabin

Twin berths on either side with reading lights

Vanity desk, mirror and chair in the centreline forward

Storage lockers beneath berths

Folding pullman berth above inboard berth

Hanging locker outboard aft of berth

Hull window with curtains

Ensuite head finished in varnished teak and rose pink marble with goldplated taps and hardware

Washbasin, shower compartment, mirrors, storage lockers and Tecma WC

Aft Starboard Guest Cabin

Twin berths on either side with reading lights

Vanity desk, mirror and chair in the centreline aft

Storage lockers beneath berths

Folding pullman berth above inboard berth

Hanging locker outboard aft of berth

Hull window with curtains

Ensuite head finished in varnished teak and forest green marble with goldplated taps and hardware

Washbasin, shower compartment, mirrors, storage lockers and Tecma WC

Main Saloon

The raised salon is all on one level, designed so that a person of average height can look out the side windows while seated.

On port, there is a large U-shaped sofa with a full size with a rosewood dining table with seating for eight. There is custom stowage for china, stemware and silverware. Forward of the sofa are full engine controls, all of which can be hidden in a lifting cabinet.

L-shaped settee with a coffee table on starboard near the retractable 42” television

On the aft side of the settee is a full bar with Volga Blue granite counter tops and custom glass and bottle stowage.

Forward Starboard Guest Cabin

Single fixed lower berth with folding pullmann berth above

Vanity/writing desk inboard with chair

Ensuite head finished in varnished teak and red crystal marble with goldplated taps and hardware

Marble bathtub, washbasin, mirrors, storage lockers and Tecma WC

Control Room

A control room is located between the main saloon and galley on the port side. This room contains the main electrical switchboards including alarm and supervision panels. There is office space with a desk and full navigation instruments. Ample shelves for storage of manuals and files are provided

Crew Cabins

There are two crew cabins forward. The port crew cabin has a larger lower berth and a single berth above. The starboard cabin has a single lower berth and a Pullman upper berth. Both cabins have an ensuite head with Tecma fresh water flush toilets.

Crew Mess

Aft of the crew cabins and across from the galley is the crew mess. Here there is a U-shaped sofa with seating for five. Outboard of the sofa is a Pullman berth. Across from the mess in an upper galley cabinet is a 20” Bang & Olufson TV

Galley

The galley is aft of the crew cabins and to port with a crew mess opposite to starboard. The galley is a large and U-shaped with Labrador Blue Pearl granite counter tops, Miele appliances, and custom storage cabinets.

Galley Equipment

Miele 4-burner KM 93-2 gas stove with electric over and grill. The stove is gimbaled and has sea rails. (New 10/10)

Miele 2-burner Hob, KM 400 8 kW

Miele Refrigerators (2) K821i

Miele Freezers (2) F423i

Miele Microwave. M636 (New 10/10)

Miele Dishwasher Professional 7855 (New 10/10)

Metos Icemaker

Miele Professional Washer 5065 (New 10/10)

Miele Professional Dryer, T5136 (New 10/10)

Iceberg wine refrigerator

Engine Room

Full headroom engine room below main saloon floor. There is an aluminum workbench, bookshelves, parts shelves and tool storage.

ENGINE & SYSTEMS

Main Engine

MTU 6R 183 TE72 marine diesel. Rated @ 305 Kw/414 Hp at 1900 RPM. CP Marine reduction gear type Mekanord 270 Hs/LS. Drip trays under the engine and diesel generatoss are connected to an electric waste oil drain pump via a valvel chest. Engine and redcution are supported on flexible mounts to minimize noise and vibration

Fuel System

Fuel tanks, lines and hoses all cleaned in 2016

Fuel capacity approx. 6,500 l in six stainless tanks, each with individual level indicators.

Shut-off valves for each tank. Tanks are equipped with hatches of adequate size to permit inspection and cleaning, vented to deck edge.

The feed line to the main engine is equipped with dual Separ fuel filter/ water separators with water alarm mounted so as to permit uninterrupted running of engine while changing filter elements.

Each diesel generator has its own single Separ fuel filter/water separator with alarm. Day tank supply has Dual Racor filters to pre filter fuel prior to entering day tank.

Propeller & Shaft

Pulled and serviced in 2015, new seals and bearings. Propeller shaft made of high-tensile corrosion resistant steel with flexible shaft coupling. Drip- free shaft seal. Shaft supported by water-lubricated rubber bearing at bracket and stern tube. Hundestedt 4-bladed variable pitch skew-back propeller with feathering position.

Thrusters

The vessel is fitted with bow and stern thrusters. Both units are hydraulic, retractable Sanders 45 kW and are driven by PTO on the main engine reduction gear. The thrusters produce approximately 600 kp thrust each.

Vibration and Noise Control

In the design of the interior and technical systems great care has been taken to reduce vibration and noise in the accommodation and recreation areas of the vessel. The design of the structure is undertaken with due regard to minimizing the transmission of vibration and noise to the main hull, interior, mast, etc. Attention has been paid to the selection of ventilation fans and machinery and to their location onboard with the objective of avoiding excessive noise levels in accommodation spaces, deck recreation areas and navigating positions.

Partitions between cabins, toilets, corridors, etc. are built to meet a 30 dB (A) level of airborne sound insulation. Doors are of similar construction and have closing seals which ensure acoustic seal. All hardware is of a type designed to eliminate rattling.

Hydraulic System

The hydraulic system is a ring system with power from four different sources:

- Main engine PTO,

- Port generator PTO

- Starboard generator PTO

- (2) 5 kW DC electric motor standby pump units

The hydraulic system is PLC controlled and supplied by Rexroth.

The hydraulic system operates the following systems:

- Reckmann RF 90-5 hydraulic furling headstay

- Southern Spars hydraulic furling main boom

- Rondal captive winches for main halyard, main sheets

- Rondal captive winches (2) for main sheets

- Rondal captive winches (2) for jib sheets

- Rondal captive winch for main halyard

- Rondal captive winches for runners

- Navtec –110 boom vang

- Navtec out haul

- Navtec twin backstay cylinders with fail safe turnbuckles

- Navtec jib halyard tensioner

- (7) Lewmar hydraulic deck winches

- Sanders 45kW bow thruster

- Sanders 45 kW stern thruster

Plumbing

Pressurized and hot/cold freshwater to all heads, galley, deck wash outlets on fore, mid and aft deck. Water capacity approx. 2,500 litres in (2) stainless tanks with one filler line from deck terminating at valve chest in crew quarters. City water connection with kinetic water softener and filter that allows shore water supply to be piped directly into the pressure water system via a pressure regulator and check valve. There is an active carbon filter for icemaker. A “water fixer” system with a 5 micron plated filter micron mesh, carbon block filter and UV chamber is installed on the cold water supply to the galley.

Watermaker

Sea Recovery water maker, Coral Sea 13M3/SW/S1 with a production of 544 l/h (144 US gal/h) is equipped with remote monitor. The water maker is provided with dual 5-micron pre-filters and an oil/water separator.

Sanitary

There are Tecma Prestige 56, 24 V in all toilets and use fresh water for flushing, discharging directly to SS holding tanks. 2x Black water and 2x Grey water tanks, all drained by electric Rheinstrom pumps with back up system

Bilge Pumps

There are five separate bilge pumps, for forepeak, forward, engine room, aft and lazarette bilges. Each pump is equipped with a DC driven submersible pump at 140 l/min (37 US gal/ min) minimum. Two manual Whale Titan are installed as back up pumps, one for fore peak and forward bilge, and the other for aft and lazarette bilges. An engine driven manual clutch pump at 250 l/min (66 gal/min) is installed as a backup pump for engine room bilge

Ventilation Systems

Forced ventilation in all cabins. Exhaust ventilators in heads and galley, and engine room. Engine room has an air inlet with water trap. Two fans are provided, one for inlet and one for exhaust. Power supply to the fans is interrupted on engine room fire extinguisher release. Fans are both pressure and temperature controlled.

Air conditioning

Condaria 25 kVA/90,000 BTU with cooling compressors and fan coils. The system can be run via the generator or shore power. Fan coils have drip pans with drains to sump.

ELECTRICAL SYSTEM

DC System

The service batteries are maintenance free gel type and consist of (2) individual 24 V banks referred to as service battery 1 and 2. Each bank has a capacity of 24 V 2000 Ah/8 h.

The starting batteries are maintenance free semi-traction type and consist of (2) individual 24 V banks. One is for the main engine and the other is common for both generators, each are 24 V 200 Ah/20 h. There is also a 24 V 55 A battery for supply to main engines manoeuvring system

- In an emergency situation the radio batteries can be supplied by main engine start batteries.

- The DC loads can be switched in groups (inverters, hydraulic power pack and general DC consumers) to one of the service battery banks

- There is a paralleling for the engine start batteries and the service battery bank #2

- There is a paralleling button for diesel generator starter batteries and service bank

AC system

The AC system is a 400 V three phase five-wire AC system. The AC system can be fed either by the diesel generators, shore power inlet or from DC/AC inverters. All AC system is equipped with a PLC- controlled power shedding system.

Generators

2x Northern Lights M445D 35 kW. The generators are mounted on hydro elastic sound/vibration absorbing seating, inside proprietary sound shields.

Shore power

The AC shower power outlet is located on the transom via a hatch. The inlet leads to an Atlas Energy System frequency converter, 30 kVA. The frequency converter accepts inlet voltages of 180-500 V AC, 47 to 63 Hz, 1 or 3 phase. The shore power cable is 15 meters and is stored in a bin by a Cable Master unit.

Charging

The service batteries are charged by 120-amp alternators on the main engine, one for each battery bank. The starter battery for the main engine is charged by a 55 A alternator on the main engine. These three alternators are equipped with external three-step voltage regulators, voltage sensing at the batteries.

The diesel generator starting battery is charged by a 24 V/35 Ah alternator on each generator.

Inverters

There are (2) Mastervolt 24/6000 VA inverters

One Mastervolt 24/3000 VA for refrigeration appliances:

One Mastervolt 24/3000 VA for entertainment

One Mastervolt 24/1000 VA for 110 outlets

ELECTRONIC SYSTEMS

Sailing Instruments

Brookes & Gatehouse H3000 (New 2010) with a central processor unit, performance processor unit, masthead unit, speed/temperature sensor, depth sensor and external alarm as well as a Halcyon 2000 electric compass.

Displays include:

2x FFDs located in control room

2x FFDs each helm

1x FFD in Owner’s stateroom

1x FFD in port crew cabin

1x FFD in starboard crew cabin

1x FFD in crew mess

1x FFD in saloon

4x 20/20 repeaters in saloon

5x 20/20 repeaters in cockpit

Analogue 360degree and 45degree wind direction repeaters at each helm

Heel angle, trim and barometric pressure sensors are also provided

Navigation Instruments

Simrad radar/chart plotter with screens in control room, saloon and at each helm

Simrad autopilot system drives the steering quadrant via twin cylinders.

A control unit is positioned at both steering stations.

Simrad gyro compass RGC 50

Nobeltec chart plotting software viewable on PC screens at nav station and saloon helm position

Computer Systems

One navigation computer, one communications computer

Communications Systems

Icom VHF

3G receiver and wireless router

SSB Icom M710RT with 150 W output

Entertainment Systems

Aft Stateroom

42” Bang & Olufson TV and sound system

Guest cabin port & starboard:

42” Bang & Olufson Plasma TV and sound system

Sony Polyplanar M905 speakers

Saloon:

42” Plasma Bang & Olufson TV and Sound System

Multi Region DVD

Bose stereo Lifestyle Series 25

Cockpit:

Bang & Olufson Sound System linked to Main Saloon

Guest cabin forward:

Bang & Olufson Sound System linked to Main Saloon

MAST & RIGGING

Mast was removed and serviced in 2015 by A+ Rigging Mallorca.

Southern Spars four spreader rig built of autoclave cured pre-preg T300 carbon fibre.

External stemball tangs and luff track for mainsail in-boom furling.

Tapered masthead with pivoting MPS block and three halyard sheaves.

Internal wiring, shielded in PVC tubes secured to mast. Ventilation conduits.

Pre-preg carbon fibre spreaders

Integrated lights up and down

External storm trysail track

Mast painted Awlgrip oyster white

Main boom

Carbon fibre roller furling boom form Southern Spars in New Zealand. Boom furling is hydraulic with a PLC controller with a two-axis joystick on each steering pedestal. The furling mandrel is carbon fibre and operated by a hydraulic motor in the outboard end of the boom. Boom has built-in deck lights. The furling system has manual back up system.

Spinnaker pole

Tapered carbon fibre spinnaker with offshore end fitting mounted on mast.

Headsail roller furling

Reckmann hydraulic headsail furler RF90-5 with aluminium foil sections

Rigging

Solid Navtec round rod rigging for upper, lower and intermediate shrouds

All rods dye-tested in 2015, replaced as necessary

Navtec series C890 turnbuckles on shrouds

All running rigging replaced and upgraded recently

EQUIPMENT

General Equipment

Castoldijet Jet Tender 15 with Yanmar 4JH3-TE 125HP engine (new 2015)

Safety Equipment

2x 8-person life rafts

1x MoM and 1x Jonbuoy mounted on pushpin.

Jack stays

Portable fire extinguishers in every cabin

Total flooding system for engine and generator space with remote control in control room

Fixed fire extinguishers behind main switchboard in control room